MSc. Thesis – Optimization of electropolishing process of needles for IVF

Are you a master student with an interest in developing more sustainable processes of medical devices? Here is your chance to join an interesting Master Thesis project with us!

Do you want to take part in developing more sustainable processes of medical devices? Chalmers Industriteknik on behalf of Vitrolife are looking for an ambitious student(s) who is interested in sustainable development and inorganic chemistry.

Background

The Vitrolife Group is a world-leading global provider of medical devices and genetic testing services.

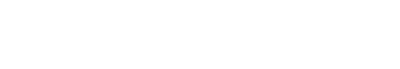

Needles are a central product in the reproductive field used both in the start to retrieve oocytes for fertilisation but also for diagnostic purpose on pregnant women, see Figure 1. The product range further hosts needles for therapeutic purpose of cyst removals and administration of local anaesthesia.

Figure 1. To the left: illustration of oocyte retrieval during IVF treatment, to the right: needle incl. packaging.

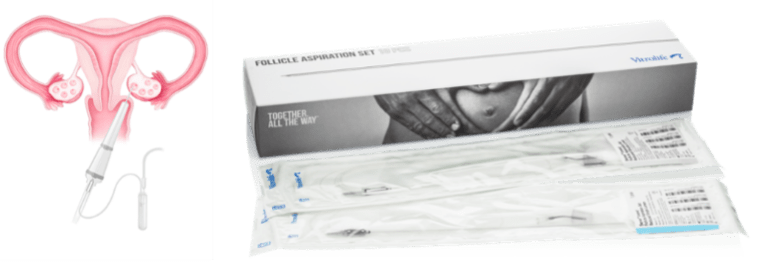

During production of the needles, they go through an electropolishing step, see Figure 2. Electro- polishing is a process where a metallic object is immersed in a heated electrolytic solution and a direct current is connected to the process and metal ions are carried from the surface of the object. The aim is to remove sharp edges and uneven features. The stainless steel that is used contains nickel that forms soluble nickel salts making the spent electropolishing solution hazardous. The project aims at reducing the nickel content and/or reclaiming nickel from the electropolishing solution.

Figure 2. The electropolishing process at Vitrolife, Göteborg.

Scope

This thesis work includes:

- Performing a literature study on electropolishing and nickel sulphate handling.

- Planning and performing practical experiments with the aim to reduce the amount of nickel sulphate during the electropolishing process, e.g., by filtration, precipitation, adjusting process parameters etc.

- Analysis and interpretation of the results, e.g., come up with suggestions for improving the efficiency and/or sustainability of the process.

- Presenting the findings to internal and possibly external audiences.

Suggested starting date will be in January 2025.

Want to contribute to a sustainable future? Apply here!

To apply for this project please send us your CV and a short introduction letter (100-200 words). Deadline for application: 19 January 2025

Supervisors will be Per Norder, process engineer at Vitrolife, and Elis Carlström, senior advisor at Chalmers Industriteknik. Examiner will be Prof. Lars Öhrström, Inorganic Chemistry, Chemistry and Chemical Engineering.

Suitable MSc programs: Innovative and sustainable chemical engineering, Materials chemistry, Biotechnology.

We look forward to your application!

- Avdelning

- Examensarbete

Göteborg

Om Chalmers Industriteknik

Vi gör morgondagen redo för framtiden

Chalmers Industriteknik är en forsknings- och utvecklingsorganisation med fokus på innovation för ett hållbart samhälle. Våra experter arbetar nära forskningen, akademin och industrin för att från forskningen skapa konkreta och hållbara lösningar på morgondagens utmaningar.

Koncernen Chalmers Industriteknik består av Stiftelsen Chalmers Industriteknik och dotterbolaget CIT Renergy.

MSc. Thesis – Optimization of electropolishing process of needles for IVF

Are you a master student with an interest in developing more sustainable processes of medical devices? Here is your chance to join an interesting Master Thesis project with us!

Läser in ansökningsformuläret

Jobbar du redan på Chalmers Industriteknik?

Hjälp till i rekryteringen och hitta din framtida kollega.